I've read lots of tutorials over the last year or so on how to make a home-made cheapo light box so I didn't have to shell out 100s of dollars for a professional set up. While I may not get the *full* advantage of a professional set up, I shall eke my way through, using this.

I got the bright idea to take pictures along the way, and post a blog! This is the first time I've ever trying to capture a process in pictures, and it lengthened the time it took me to complete it. I'd say I spent about 3 hours doing it - I'm slow and methodical with it comes to doing something new. I didn't want to make any major mistakes as I didn't have any extra foamboard on hand. Also as I moved along in the process, day turned into early evening and I had to use the dreaded flash.

WHAT I USED

2 pks of 12" x 18" bi-fold white foam board - I used Elmer's (does not have to be bi-fold but it helps)

1 exacto knife, or a soldering wand with an exacto tip (I used the Philips Screw Cordless Soldering Kit)

1 roll packing tape, 1 1/2" - 2" wide

1 roll invisible tape or masking tape (not shown below)

4 - 8 sheets of vellum paper standard size 8.5" x 11"

tape measure or ruler

a pen or pencil

a non-flamable, surface to work on if you're using the soldering wand

scissors (not shown below)

scissors (not shown below)

hot glue gun (optional, and not shown below)

*All items in this list cost me around $20.00 give or take a few bucks.

*All items in this list cost me around $20.00 give or take a few bucks.

***Please use proper safety precautions when using exacto knives, soldering wands and hot glue guns. I cannot be held responsible if you slice off a finger, poke yourself in the eye, burn a hole in your dining room table, or blister your fingers with the hot glue (like I did). Be safe!!

|

| Not shown: scissors and glue gun. I will be cutting with the soldering wand on top of that thick piece of board underneath everything. |

|

| Got this a WalMart for less then $2 each |

To get started, take one of the bi-folds (or if you're not using that, then just take a panel of the foam board) and mark your lines where you will cut. We're creating "windows" in all but one side of the light box. This allows the light through. Later I'll go over covering them up so that the light does not cause glare. We never want glare on our jewelry!

Measure one inch in on each corner (1" in and 1" over), then connect the lines. The lines are where you will cut.

|

| You will probably need to pass through each line 2 or 3 times to get a clean cut. Press down firmly! |

|

| 1st window is cut out. The "line" you see on the left is the fold line of this bi-fold panel. |

Next, I needed to cut the other panels to be able to square up to the first one. I set up the panel I just cut and then brought the 2nd bi-fold panel up next to it (while still folded) so that it is placed on top of the base, not to the side of it. (Take a look at the 3rd picture down - it demonstrates what I mean.) I'm going to have to tape it together later and this is the best configuration for that. I've turned the bi-fold on it's long side to stand up, so there will be a strip to remove.

|

| After the mark is made, I will use that mark as a gauge where to place other marks across the whole bi-fold panel to remove the strip. |

|

| Cutting the strip off the 2nd panel, 2nd side. I've already cut off the 1st half of the strip. I've also marked my 1" lines on one side of the bifold to prepare to cut out the window. |

Here it shows what I mean about squaring up the panels.

Next, I'll be cutting a window out of each side of the bi-fold. I cut one out, then I cut the fold of the bi-fold so that I had 2 separate panels. I placed my first panel that already had the window cut out of it onto the second panel to use as a guide to make my lines on the 2nd one. It was a lot quicker than measuring again.

*Just beware that if you did not cut straight lines out of the first panel, you won't have straight lines to use for your second one, so just do what Bob Vila did. Measure twice, cut once.

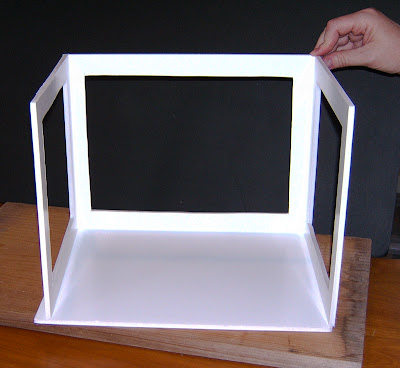

Now I have 3 windows.

Next I will glue the right and left walls/panels to the base with the glue gun. I had to be sure of the best fit, so I moved it around from side to side then I applied the glue to what ended up being the bottom. I placed it on the edge of the base and had to reposition it a bit. Some of the glue now shows from when it squished out from me moving it around. After about 30 seconds I did the 2nd side. You can see that the first side stands up all by itself. Foam board is very light.

|

| The sides are upright on their own now, with just the glue holding them in place. |

|

| Finishing up the last of the tape... all done! |

Thanks for visiting!!

6 comments:

That looks terrific, Jeanne. You did a great job.

Thanks Michele!

That's wonderful! Bravo! :)

Thanks Ness, I appreciate you leaving a comment. :)

Jeanne (Queen Jeanne) Your light box procedural is great! AND after looking at your jewelry on FB it is obvious that you can do anything you set your mind to!! I might be concerned if you tried soldering BLINDFOLDED! LOLOLOL

You're awesome girl!

Patricia you just made my whole week!(and it has been a duzy lemme tellya)... thank you so much for those kind words, it means more than you know. :)

If it's all the same to you, I think I'll skip the blindfold. LOL!!

Post a Comment